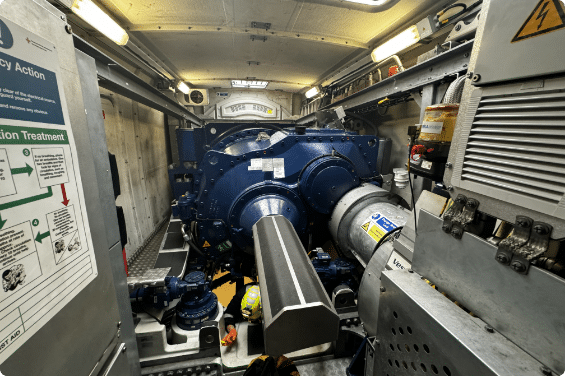

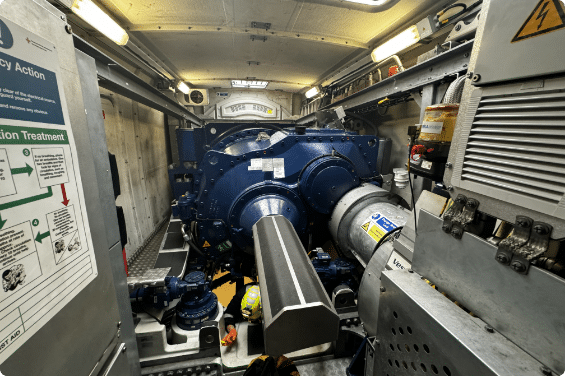

Advanced sensing equipment, software and analytics help to identify faults early, reducing asset downtime.

Condition monitoring involves the use of sensing equipment, together with data analytics that continually assess the performance and health of a wind turbine. This allows for early detection of potential issues, predictive maintenance scheduling and optimisation of the wind turbine asset can all increase energy production and reduce downtime. Examples of items monitored can include changes in vibration, temperature, oil condition, power, speed…

Simply fill out the form below and one of our freindly experts will be in touch.

A Proactive Approach to Wind Turbine Maintenance

Embracing a proactive stance, Spectrum Wind Services’ Condition Monitoring ensures onshore wind turbines operate at peak efficiency. By leveraging advanced diagnostics, we enable early issue detection and optimise performance, significantly reducing downtime and enhancing energy output. This approach not only extends turbine lifespan but also supports the shift towards more sustainable and reliable renewable energy operations.

Precision in Every Aspect of Maintenance

Through meticulous condition monitoring, Spectrum Wind Services guarantees that onshore wind turbines achieve superior efficiency and reliability. Our precise diagnostics facilitate swift issue identification, allowing for immediate optimisation actions. This method drastically cuts downtime and boosts energy production, ensuring turbines operate smoothly and sustainably, aligning with the global push for dependable renewable energy sources.

Below are some of our most popular frequently asked questions

Condition Monitoring is a proactive maintenance strategy that uses advanced technology to monitor the real-time condition of wind turbines. It involves the continuous collection and analysis of data from various turbine components to identify anomalies, predict potential failures, and facilitate timely maintenance actions. This approach helps in preventing unexpected breakdowns and optimising turbine performance.

Implementing Condition Monitoring across your wind farm brings numerous benefits. It significantly reduces the likelihood of unexpected turbine failures, minimises downtime, and ensures your turbines operate at optimal efficiency. This not only extends the lifespan of your turbines but also improves overall energy production. By preventing major breakdowns, Condition Monitoring can lead to substantial cost savings and a more reliable energy supply.

Absolutely. Our Condition Monitoring system is designed to be retrofitted into existing wind turbines with minimal disruption. We work closely with your operations team to ensure a seamless integration, allowing you to start benefiting from advanced diagnostics and predictive maintenance without the need for major modifications to your current setup.

© 2023 Spectrum Wind Services. All rights reserved.

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking ‘Accept All’, you consent to the use of ALL cookies. However, you may visit ‘Cookie Settings’ to manage your consent and ‘Opt Out' of any cookies, depending on your preferences